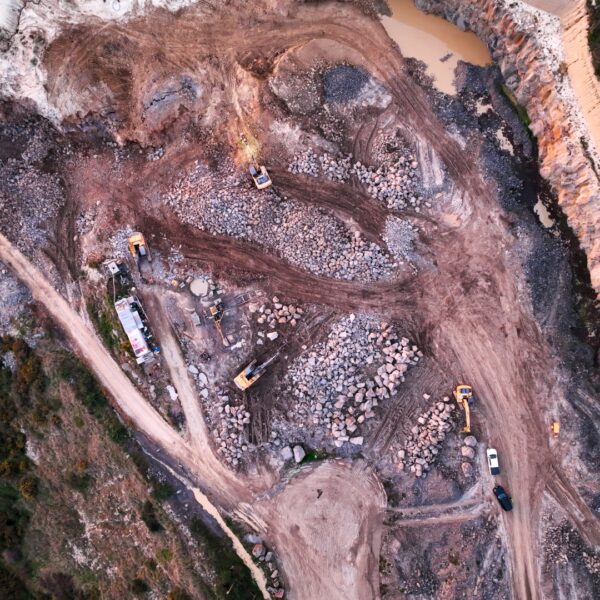

Timaru — Fraser road Blue Stone Quarry.

Who Rooney Earthmoving are

Rooney Earthmoving is a long‑standing New Zealand civil contractor covering earthmoving, irrigation, pipe and cable laying, cartage and transport. They operate across Waimate, Ashburton, Christchurch, Timaru and Oamaru with a staff of roughly 200. The group began in 1976 when Gary Rooney started with a single bulldozer in Waimate — very South Canterbury beginnings for a company that’s grown into a recognised name.

How West-Trak supports Quarry & Civil fleets

The wear parts you see working on a machine like this Komatsu PC300 — and across fleets like Rooney’s — are the core of West-Trak’s operations:

- Undercarriage — Chains, track shoes, rollers, idlers, sprockets and more; track group assembly, on-site advice and reporting.

Explore: Undercarriage parts - G.E.T (Bucket teeth & adapters) — Tooth systems like our unique MTG suited for all Quarry & Mining applications, optimised for each machine and site.

Explore: MTG Bucket teeth - Bucket & Blade Wear Protection — Bolt-on edges, side cutters, heel shrouds, liners, and custom bucket wear protection.

Explore: Bucket & Blade Protection - Steel Plate & Liner Solutions — Abrasion-resistant steel, profiling and fabrication for chutes, buckets, fixed quarry plant, crushers, screens and more.

Explore: Steel Plate & Capabilities

Proof in the field:

- Screen media that lasts: Greystone Screening & Crushing switched to heavy-duty punch plates on aFinlay 883+ top deck to stop mech failures — cutting downtime and replacement costs.

- Dozer undercarriage done right: Alex Mason Contracting’s Komatsu D65EX-15 received a full undercariage replacement to handle abrasive riverbed work in Caterbury.

Why this matters on hard rock

- Predictable wear enables planned maintenance instead of mid-shift surprises.

- Right parts, fitted right shortens stoppages and keeps production steady.

- Local stock + support means fewer “machine down, crew waiting” moments.