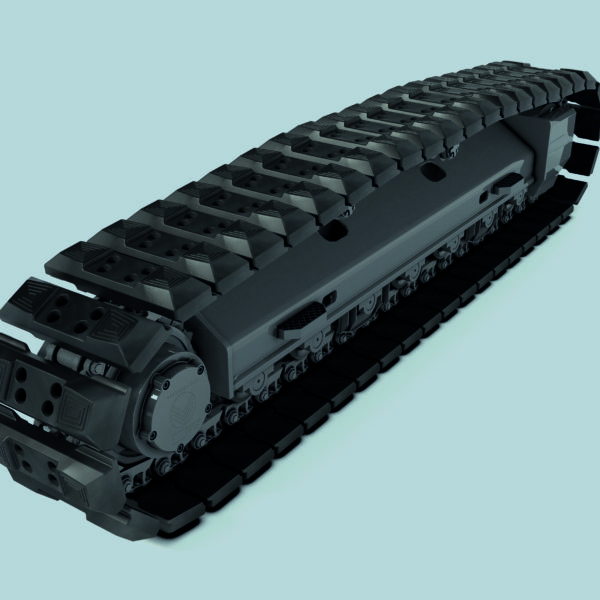

Designed for surface protection and to reduce noise, West-Trak rubber track pads are a durable addition to excavators working in roading, civil construction, rail, demolition, or drainage applications.

The most popular style. Bolt-on rubber pads are secured to existing steel track shoes that have been pre-drilled for rubber pads. This secure attachment maximises durability, extending the life of the rubber pad. Bolt-on rubber pads are available for excavators from 3-30 tonne.

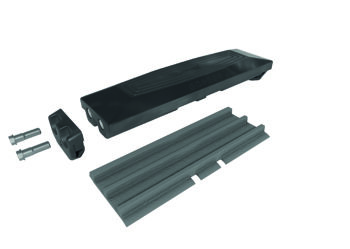

Easy to install and remove on-site; clip-on pads are best suited when your machine doesn’t have pre-drilled grouser plates for bolt-on rubber pads. Clip-on rubber pads simply fit over the width of the steel track shoe and clip over each end of the plate. These versatile pads are available for excavators from 3-30 tonne. Only 2 bolts need to be removed, reducing fitting and removal times.

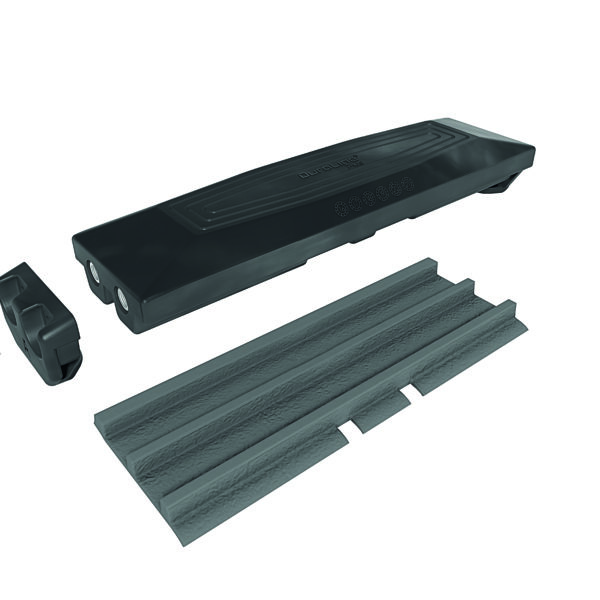

Chain-On Rubber Pads (Roadliner Pads):

Unlike bolt-on or clip-on pads, these pads are fixed directly to the track chain. They attach using track bolts, replacing the steel track shoe entirely. These are suitable for 8-15 tonne excavators and best suited for permanent application to your machine.

Frequently Asked Questions:

Which Rubber Pads last the longest?

-

- Chain-on rubber pads are best suited for long-term use, as they are a more permanent application with a longer wear-time due to higher durability and thicker rubber.

- Bolt-on rubber pads are also highly durable with secure fitment ensuring longer wear life and less debris build-up between the pad and the track shoe.

- Clip-on rubber pads typically have the shortest lifespan, with material build-up under the pad or broken clips on each end often reducing their usability over time.

Which Rubber Pads are the easiest to install or remove?

-

- Clip-on pads are the quickest to fit and remove. One key factor about the installation process of clip-on rubber pads is when fitting them to the steel shoe, only 2 bolts have to be removed, compared to 4 bolts for both the bolt-on and chain-on rubber pad types.

- Bolt-on pads take longer to fit than clip-on rubber pads because they require all 4 bolts to be secured.

- Chain-on pads require the most time to fit, as the existing steel track shoes (or chain-on rubber pads) must be removed for the rubber pads to be installed directly onto the track chain.

Which Rubber Pads are the most expensive?

-

- Bolt-on rubber pads are the cheapest option, and offer the best balance of price and lifespan, making them the most popular.

- Clip-on pads are more expensive than bolt-on rubber pads due to the additional steel clips on each end.

- Chain-on pads are generally the most expensive due to their construction of a thick steel base plate and bonded rubber. Chain-on rubber pads carry the weight of the machine, compared to bolt-on or clip-on rubber pads which are supported by the steel shoe they bolt to.

How many Rubber Pads do I need?

Excavators require one rubber pad per track shoe.

The quantity of shoes per machine varies by make and model, so get in touch with our team and we will advise the quantity required.