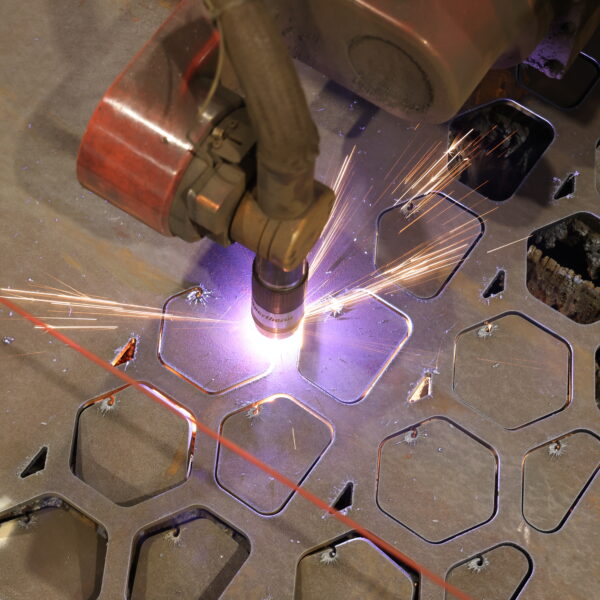

Punch plates are a critical part of a screening machine. They play a key role in separating materials of different sizes in quarrying, mining, roading, and earthmoving operations. Screen punch plates are produced from high-quality wear steel and precision-cut on our CNC plasma cutter for each machine, ensuring perfect fitment and longevity even under harsh conditions with abrasive materials.

Key features

Punch plates from West-Trak combine quality materials and cutting-edge technology to deliver the performance and reliability that is critical for screening.

Custom fit: We can supply punch plates for any screener in New Zealand and offer an on-site measuring service to ensure perfect fitment.

Premium Wear Steel: Typically produced using 450-grade wear steel for maximum wear-resistance in abrasive environments.

Customisable Patterns: From Hexagonal to round, square, or bespoke designs, we can create any hole pattern or size to meet your screening needs.

Precision Cutting: Our CNC plasma cutter ensures clean and accurate ‘punches’ for optimal performance and screening consistency.

Applications & Use Cases

Punch plates are indispensable in industries like:

Quarrying: Separating materials like gravel, stones, and larger rocks for aggregate processing.

Mining: Managing coarse materials and ensuring efficiency in material handling.

Civil Construction: Supporting earthmoving operations and aiding in the production of specific material grades.

Example in Action:

We recently supplied Finlay Group with punch plates for their Finlay 833+ screener. These plates, with hexagonal holes precisely cut to 125mm, ensured optimal material separation for their customer, Greystone Screening & Crushing Ltd at their Christchurch quarry.

Check out the case study here.

FAQs

How long do punch plates last?

Longevity depends on the material being screened. However, using high-grade wear steel enhances durability significantly.

Can you match my existing punch plate?

Yes! We can create any hole pattern requested to suit your requirements, including matching your existing plates, and free on-site measuring if required.

Learn more about our steel plate capabilities and find the right solution for your quarrying and mining needs.